Janovski complex. The signal consists of the reduc-

tion in the amount of light passing through the

reaction solution. The signal is detected by a

spectrophotometer.

Calculation of results

In order to arrive at a study result, the magni-

tude of the signal generated by a sample must be

converted to a concentration value. This can be

done in either of two ways. If the measurement

system has been shown to have signal generating

properties that closely match the theoretical ideal,

the theoretical relationship between analyte concen-

tration and signal magnitude can be used to calculate

the result. For example, the theoretical relationship

between analyte concentration and light absorbance

is embodied in the Beer-Lambert law,

analyte concentration =

absorbance

analyte absorptivity

$

light path

For an ideal system, dividing the observed absor-

bance value by the known values for the absorptivity

of the analyte and the length of the light path in the

detector yields the analyte concentration.

In practice, the behavior of measurement

systems is rarely ideal, so the use of theoretical

relationships is not a satisfactory way to calculate

results. Instead, results are calculated using the

empirical relationship between analyte concentration

and signal magnitude as established by the measure-

ment of signals produced by a set of test materials

with known analyte concentrations. These test

materials are called calibrators (formerly, standards)

and the relationship between analyte concentration

and signal magnitude is called a calibration curve.

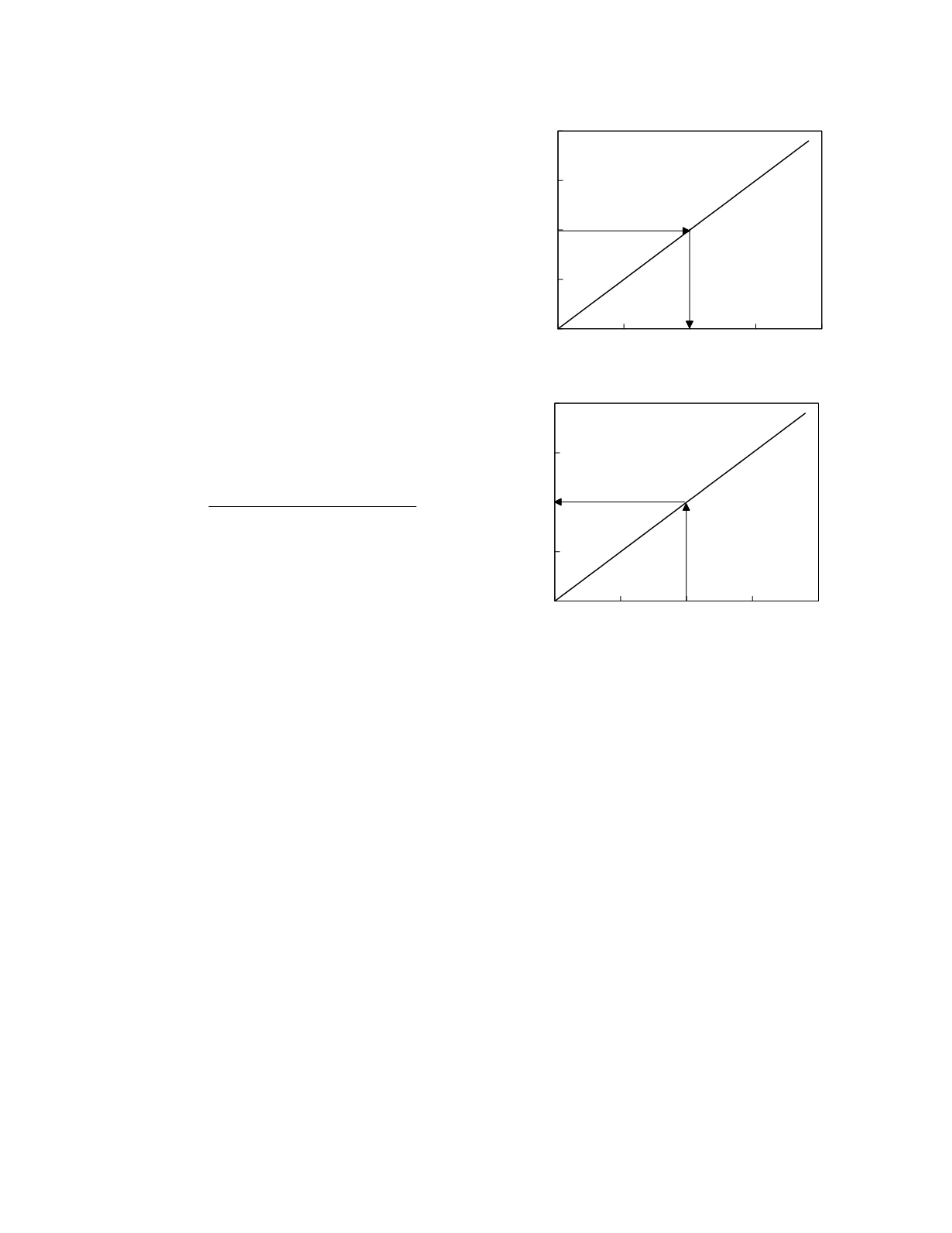

A hypothetical linear calibration curve is shown in

the upper graph of Figure 2.1

To convert the signal generated by a test sample

to a concentration value, the calibration curve is

used in reverse. That is, rather than finding the y

(signal) value on the curve for a known x (concen-

tration) value, an x value on the curve is found that

corresponds to the known y value. For a signal of

100 units, for instance, the corresponding point on

the calibration curve has a concentration of 10 units.

The measurement result is therefore, 10 concentra-

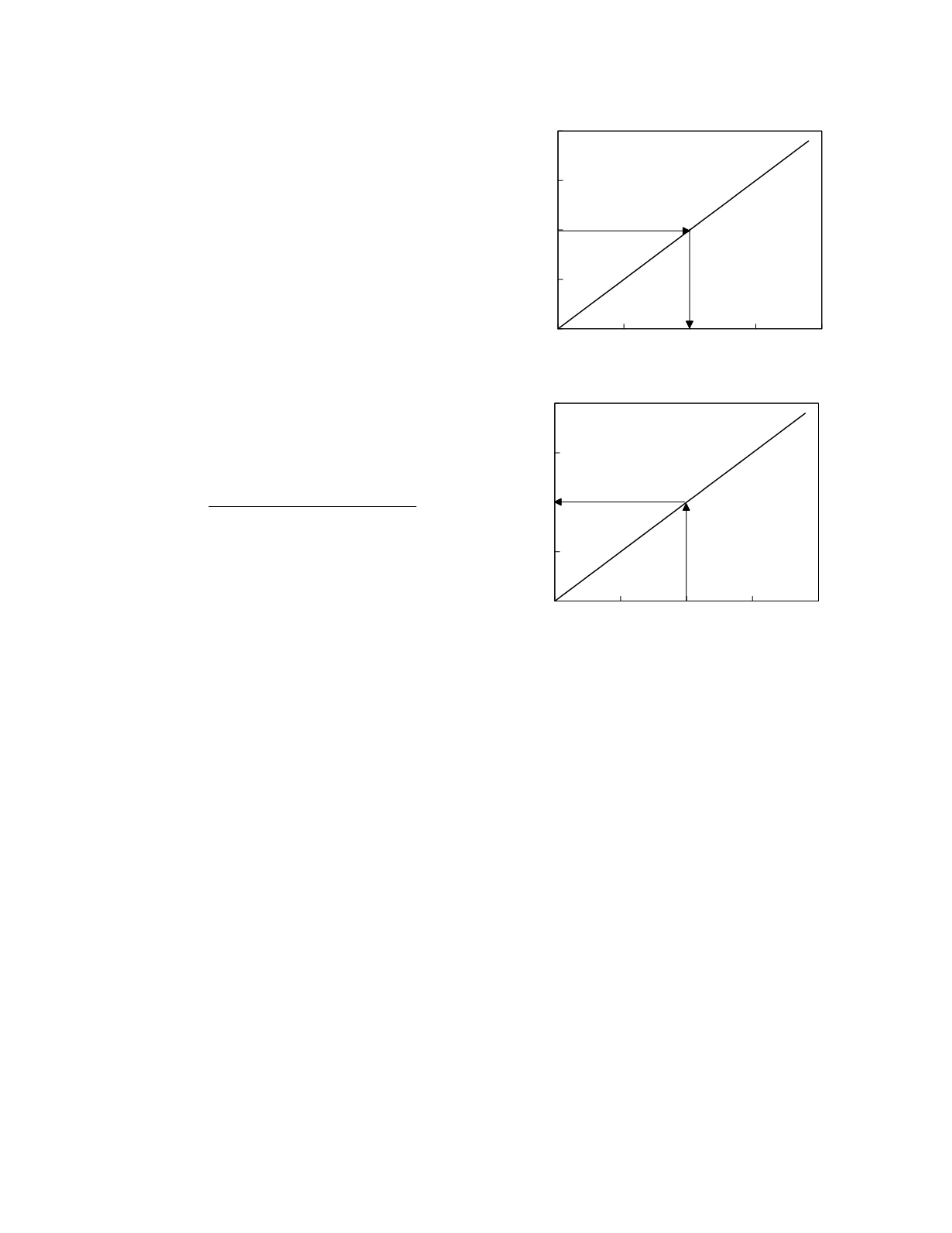

tion units. Because it is unconventional to reverse

the roles of the x- and y-axes, results are calculated

using what is called a measurement curve which is

identical to the calibration curve except that the x-

and y-axes are switched (the lower graph in Figure

2.1). Note that inversion of the equation describing

the calibration curve yields the equation that defines

the measurement curve.

Calibration and measurement curves are usually

constructed each time that a batch of measurements

is made. Calibrators are run along with the test

samples and the parameters of the equations defining

the curves are estimated from the observed calibrator

and signal magnitude pairs. The number and

spacing of the calibrators should be chosen with the

intent of providing for highly reliable estimation of

the equation parameters. According to the statistical

theory of optimal design, there exists a unique set of

calibrator concentrations that yields the most precise

estimates of the equation parameters (Fedorov 1972,

Steinberg and Hunter 1984). In general, the number

of separate concentrations that should be evaluated

equals the number of parameters in the equation. In

the case of a linear calibration curve there are two

Laboratory Methods

2-2

0

5

10

15

20

Calibrator concentration

0

50

100

150

200

Signal magnitude

0

50

100

150

200

Signal magnitude

0

5

10

15

20

Sample concentration

calibration

y = b0 + b1 x

measurement

y = (x - b0) / b1

Figure 2.1

Hypothetical calibration and measurement

curves (solid lines). The graphical technique for the calcula-

tion of the result given a signal of 100 units is depicted.