However, with two control samples per batch, the

false-rejection rate is too high, 8.9 percent. Using

the 1

3s

control rule (which states that a batch of

measurements should not be considered to be

in-control if one control result exceeds the mean plus

or minus 3 SD

within-laboratory

), an acceptable false-

rejection rate, 1.6 percent, can be achieved at the

performance goal, but at the expense of requiring six

control samples per batch. Fewer control samples

per batch can be used while still achieving the

quality control goals if a control rule intermediate

between the 1

2s

and 1

3s

rules is employed. Specifi-

cally, using three control samples per batch, the

1

2.385s

rule will yield a 5 percent false-rejection rate

and a 90.6 percent rejection rate. In general, the

best control rules in terms of control sample require-

ments are those for which the control limits have

been calculated to achieve the specific quality

control goals (Bishop and Nix 1993).

A somewhat different approach to evaluating

control performance is taken when considering the

detection of long-term, or persistent, quality degra-

dation in a method. Here the focus is on how many

batches will be accepted before the control rule leads

to a batch rejection and, thereby, detection of the

quality problem (Nix

et al.

1987). The most infor-

mative way to present this performance behavior is

as the cumulative run length distribution for the

control rule. This distribution gives the probability

of having rejected any batch, including the current

batch, as a function of the number of batches run

since the inception of the quality problem. Figure

2.6 shows the cumulative run length distributions for

the 1

2s

rule at five different levels of persistent

method bias. The graph also has a line that indicates

the medians of the distributions. For instance, the

median run length for zero method bias is 15

batches. That is the median number of consecutive

batches that can be expected to be accepted using

this control rule when the quality of the method is

unchanged. The median run lengths for the other

levels of persistent method bias in the graph are 9,

4, 2, and 1, in order of increasing bias. (Note:

average run length is the usual measure for the

evaluation of control rules in the setting of a persis-

tent problem in method quality. Because run length

frequency distributions are highly right-skewed,

average run lengths will be larger than median run

lengths. For example, the average run length for the

1

2s

control rule is 22 batches when the quality of the

method is unchanged. Compare this to the median

value of 15 batches. Because it is less influenced by

extreme run length values of low probability, median

run length better reflects the run length behavior

expected of a control rule.)

The control rule used to monitor a method for

persistent quality degradation must satisfy the clini-

cal performance and false-rejection quality control

goals for such problems. The performance goal can

be expressed as maximum median (or average) run

length at a specified level of quality decline in the

method. The false-rejection quality goal can be

expressed either as an acceptable median run length

when the quality of the method is unchanged or, as

for single-batch quality monitoring, as an acceptable

false-rejection rate per batch. Typically, single rule

control procedures are not able to provide the

Laboratory Methods

2-11

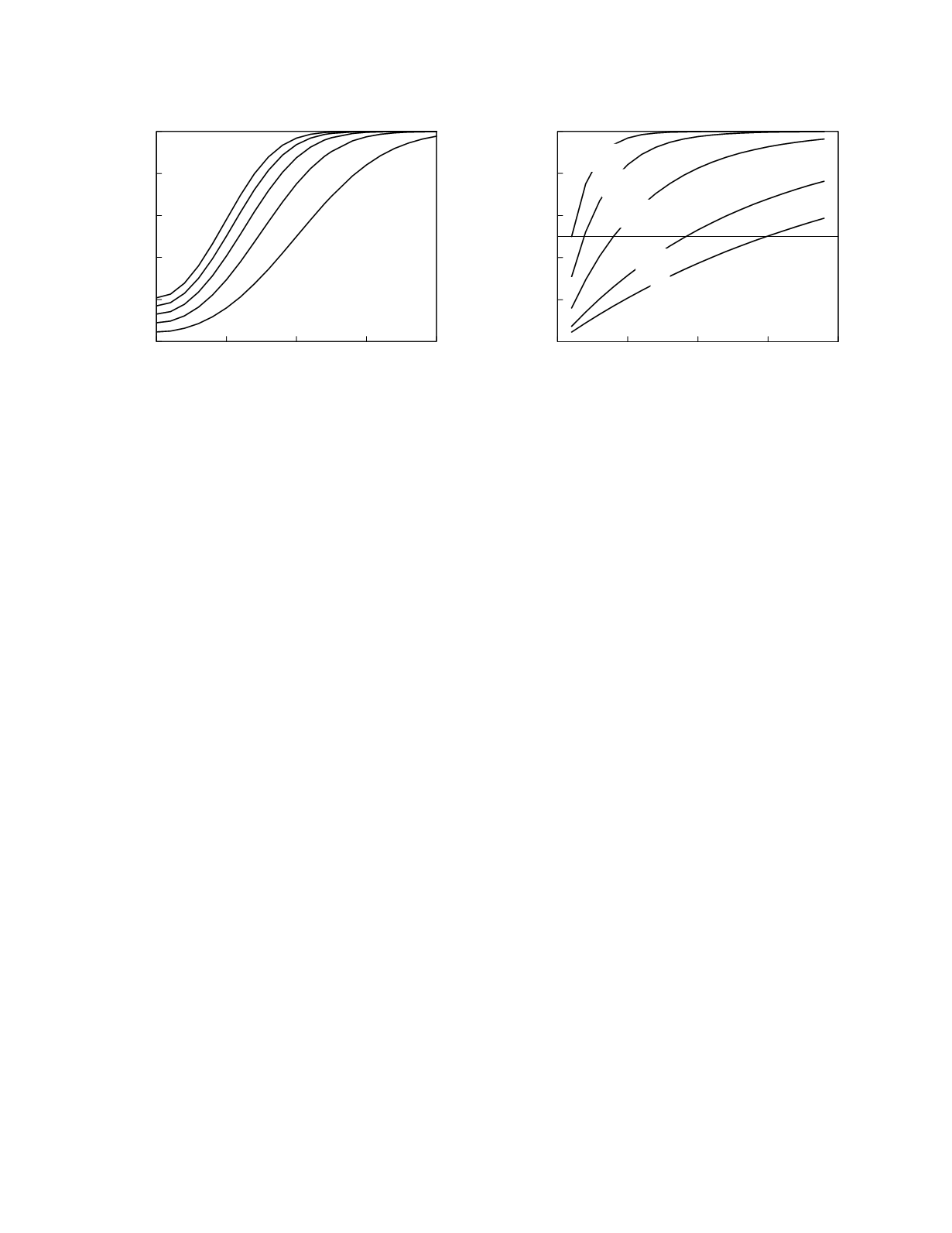

Figure 2.5

Operating characteristic curves for the detection

of current method bias using the 1

2s

control rule. Curves

are shown for one to five control samples per batch.

0

1

2

3

4

Bias (multiples of within-laboratory SD)

0

0.2

0.4

0.6

0.8

1

Rejection probability

n =1

n = 5

0

5

10

15

20

Run length

0

0.2

0.4

0.6

0.8

1

Rejection probability

0

0.5

1.0

1.5

2.0

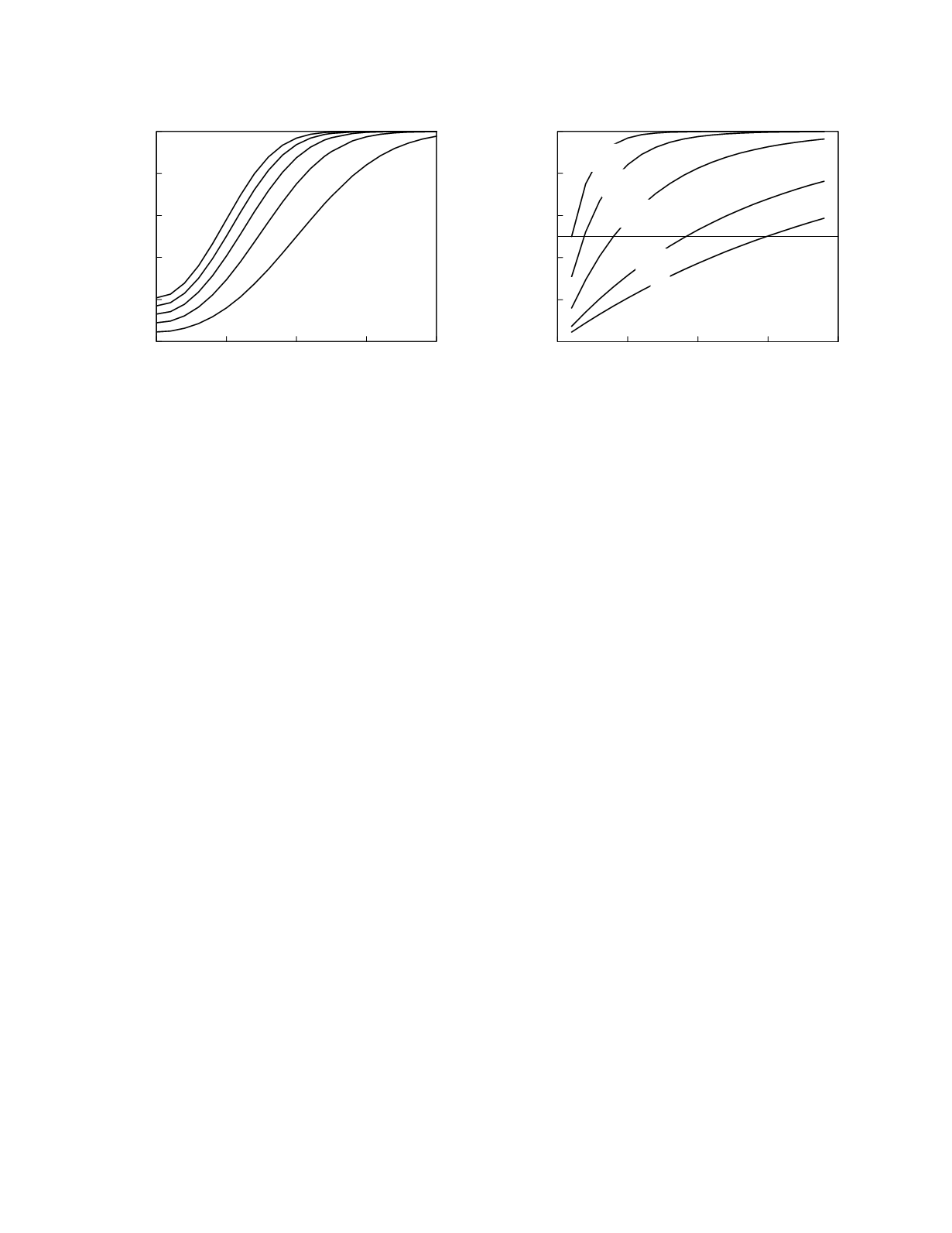

Figure 2.6

Cumulative run length distributions for the

detection of persistent method bias using the 1

2s

control

rule. Curves are shown for method bias in half multiples of

SD

within-laboratory

.